Loto Station

- Home

- Products

- Lockout & Tagout

- Loto Station

Loto Station

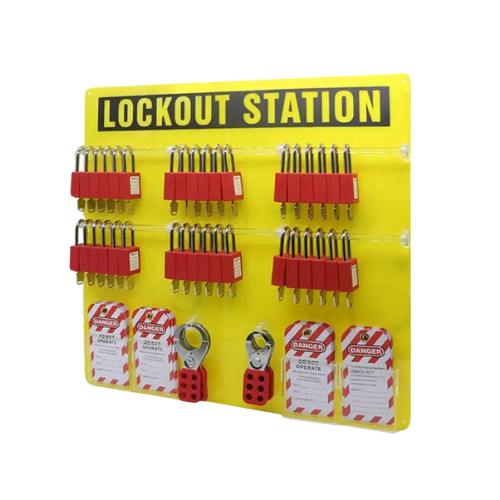

A lockout station is a designated area or setup within a workplace where lockout/tagout (LOTO) devices and equipment are stored and organized for use during maintenance, repair, or service activities. It’s a central location where workers can easily access lockout devices such as locks, hasps, tags, and other necessary tools to perform safe lockout/tagout procedures. In industrial and commercial facilities across the region, having a lockout station fully equipped with lockout tagout locks in UAE ensures that safety protocols are always followed efficiently.

Key Features of a Lockout Station:

Storage for LOTO Devices:

A lockout station typically includes organized compartments, bins, or shelves for storing various lockout devices like padlocks, hasps, breaker lockouts, circuit breaker lockout devices, and tags. These stations play an essential role in ensuring that every piece of equipment needed for lock and tagout in Dubai is always available and within reach of maintenance personnel.

Labels and Tags:

It will also have tags and markers for workers to use in order to identify the reason for lockout and provide other important information (e.g., worker name, date, department, etc.). This promotes accountability and enhances safety measures by clearly indicating who is working on what equipment, especially when using safety padlock in UAE applications.

In facilities where multiple technicians are involved, lockout stations help maintain order and standardization. Workers don’t need to search for tools across the site; everything needed is consolidated in one place. This approach is widely adopted in organizations across the UAE, especially where adherence to lock and tagout in Dubai practices is strictly monitored.

By keeping all lockout tagout locks in UAE well-organized and accessible, lockout stations support a safer and more efficient working environment. Whether for electrical maintenance, mechanical repair, or valve servicing, a well-stocked LOTO station is an essential part of any workplace safety program.

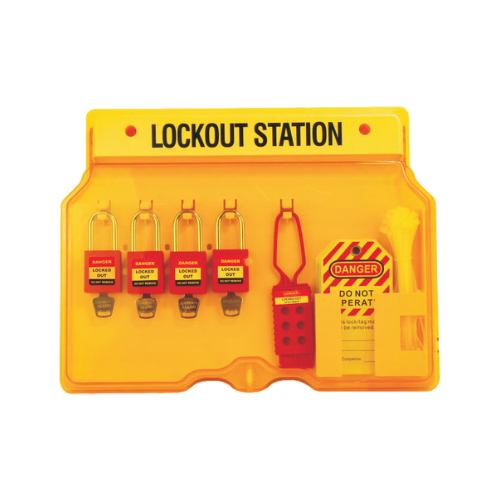

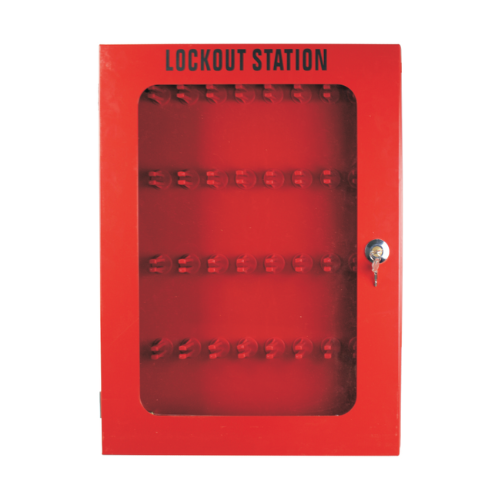

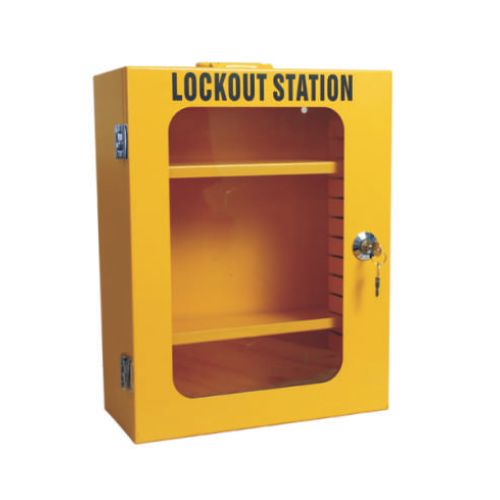

Lockout Station

Lockout Box

Lockout Stations and Boxes

Product Categories

Safety Cabinets

Lockout and Tagout

Spill Pallets

Absorbent Materials

Spill Containment Boom

Spill Containment Berm

Open Lockout Station Big

76 mm Dielectric Thermoplastic Safety Padlock with a 6 mm plastic shackle.

Material: Nylon body+Nylon shackle

Weight: 141g

Combined Lockout Padlock Station

Color: Yellow

The overall size: 520mm(W)x631mm(H)x85mm(D)

one piece design, with a cover to lock out