Lockout Tag

- Home

- Products

- Lockout & Tagout

- Lockout Tag

Lockout Tag

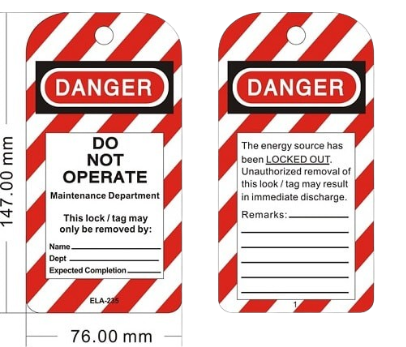

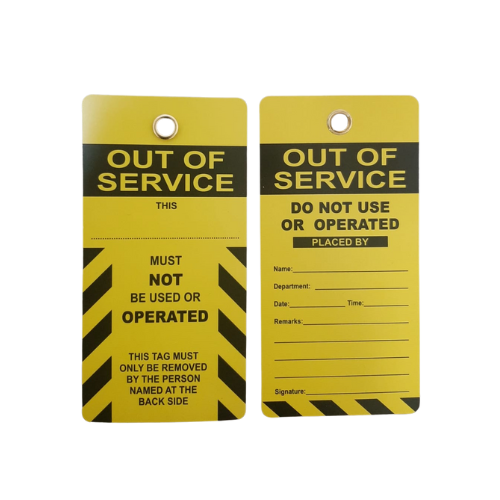

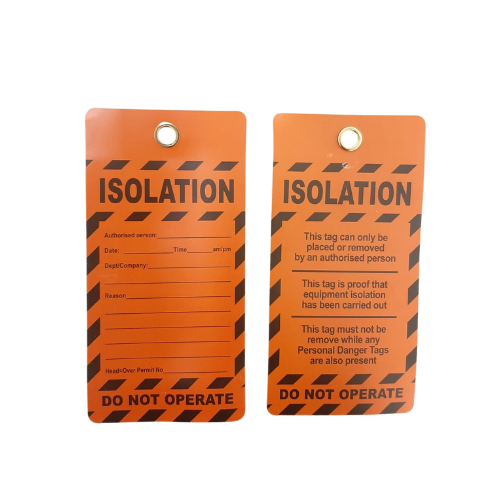

Lockout tagout tags are designed to ensure that dangerous machines are properly shut off and remain idle and tagged during maintenance or repair work. These tags help provide clear awareness to personnel and prevent accidental operations. In industrial environments, especially in regions like the UAE, these tags are used as part of standard safety practices involving lockout tagout locks in UAE.

Features of Lockout Tags

Labels and signs help communicate safety and lockout information directly at the point of use. These tags, labels, and signs are available in various materials and OSHA-compliant Lockout/Tagout (LOTO) formats. They are an effective way to visually deliver warnings and instructions for preventing unexpected machine start-ups and to alert operators about proper lockout procedures during service. When implementing lock and tagout in Dubai, such tags enhance overall safety and compliance.

Safety Padlock Labels

Safety padlock labels provide a clear message that a machine is undergoing service or maintenance. These labels are designed to fit securely onto safety padlocks and are commonly used in conjunction with safety padlock in UAE to reinforce workplace safety during lockout/tagout activities.

Lockout Tag with Detachable Key Stub

Perforated cardstock tags come with a detachable key stub, allowing for easy identification and matching of tags with padlocks. Each part has matching ID numbers, and a 10 mm metal ring is included for attaching the stub to the key. This design supports efficient tracking during maintenance and enhances control, particularly in structured lock and tagout systems.

Lockout tags play a crucial role in any lockout/tagout program. By clearly identifying who is working on what, and preventing accidental reactivation, they help create a safer working environment for everyone involved.