Hasp Lockout

- Home

- Products

- Lockout & Tagout

- Hasp Lockout

Hasp Lockout

In high-risk industrial environments, hasp lockout devices are crucial components of an effective lock and tagout in Dubai safety plan. Designed to prevent accidental machine start-ups, hasp lockouts ensure that maintenance or repair work is performed without the risk of unexpected energy release.

What Is a Hasp Lockout?

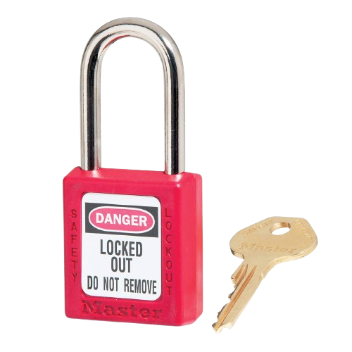

A hasp lockout is a metal or heavy-duty plastic device with multiple openings that allow several safety padlock in UAE units to be attached. It is used when more than one person is working on the same machine or equipment. The equipment remains locked and inoperable until all individuals have removed their respective lockout tagout locks in UAE.

Ideal for Team-Based Safety Lockouts

In situations where maintenance tasks involve multiple technicians, hasp lockouts allow each team member to attach their personal safety padlock in UAE. This means the equipment can’t be reactivated until the last padlock is removed, guaranteeing total safety and compliance with UAE workplace safety laws.

Combine with Group Lockout Boxes

For larger or more complex systems, hasp lockouts can be used alongside a group lockout box. Each worker secures their lock onto the hasp, while the group box stores all the keys safely. This ensures full control and accountability in line with lock and tagout in Dubai procedures.

A Must-Have for Industrial Safety

Whether you’re in manufacturing, oil & gas, construction, or utilities, using a hasp lockout with lockout tagout locks in UAE is a simple but powerful way to protect your workers and equipment. Built to fit various types of isolation points, these devices are key to creating a safer workplace.

Why Use Hasp Lockouts in Your Lockout Program?

Hasp lockouts play a vital role in improving workplace safety, especially when more than one worker is involved in maintenance or servicing equipment. They allow each worker to attach their own safety padlock in UAE to a single lockout point, making sure that the machine or equipment cannot be re-energized until all workers have finished their tasks and removed their individual locks. This prevents unauthorized or accidental startup and provides a clear indication of who is still working on the equipment.

Using hasp lockout devices not only promotes better coordination among team members but also strengthens accountability. It guarantees that every worker involved in the task is protected and in control of their safety. In places like Dubai, where safety regulations are strictly followed, incorporating hasps into lock and tagout in Dubai procedures helps organizations meet international safety standards such as OSHA.

By combining hasp lockouts with trusted lockout tagout locks in UAE, businesses can implement a more efficient and secure lockout/tagout system. This approach supports a safety-first culture in industries like construction, electrical, and manufacturing, where the risk of hazardous energy exposure is high.