Electrical Lockout

- Home

- Products

- Lockout & Tagout

- Electrical Lockout

Electrical and Breaker Lockout

An electrical breaker lockout is a safety procedure used to ensure that a circuit breaker is not accidentally turned on while maintenance or repair work is being performed. It involves physically locking the breaker in the “off” position, typically using a lockout/tagout (LOTO) device, to prevent unauthorized or accidental re-energizing of the electrical system.

Here’s a general overview of how it works:

Turn off the breaker: First, you need to ensure that the breaker is turned off before applying a lockout.

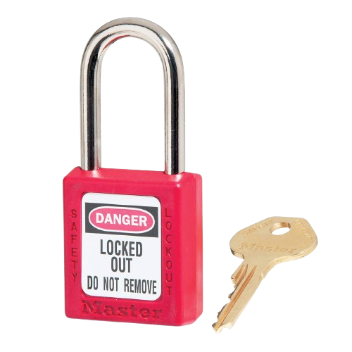

Apply the lockout device: A lockout device (such as a lockout hasp, padlock, or other mechanical lock) is attached to the breaker. This device physically prevents the breaker from being turned back on.

Tag the breaker: A tag or label is attached to the breaker to notify anyone who interacts with it that maintenance or repair work is being conducted. This tag typically includes the worker’s name, the reason for the lockout, and the date.

Verify de-energization: Always double-check that the circuit is de-energized before beginning work, using appropriate testing equipment like a voltage tester or multimeter.

Circuit Breaker Lockout

Circuit Breaker Lockout